Especially manufacturers of decorative surfaces (such as wood, ceramics, textiles, or packaging) are often faced with the challenge that the color of the print run must not deviate or deviate only minimally from the production reference – this also applies to reprints or to production at different locations. A prerequisite for this is that the color range of the output system completely covers the color space of the print job.

To meet this requirement and to reduce color deviations to a maximum, ColorGATE has developed the Out of Gamut Module:

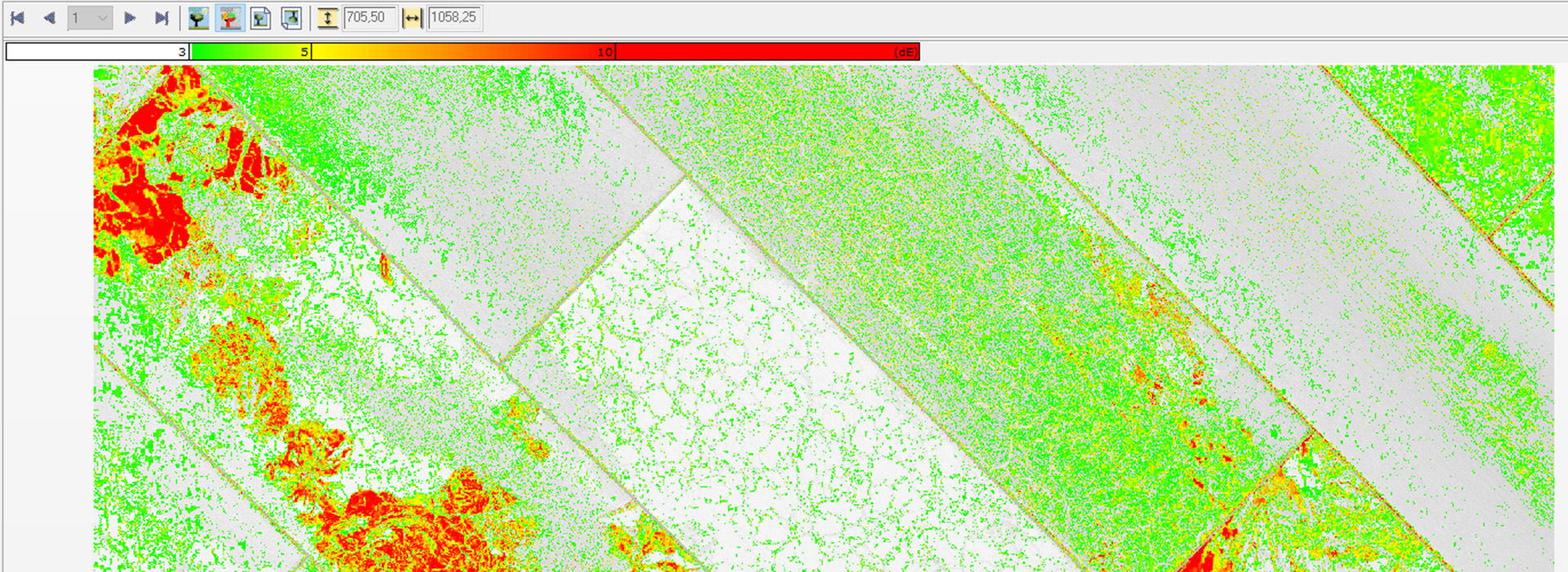

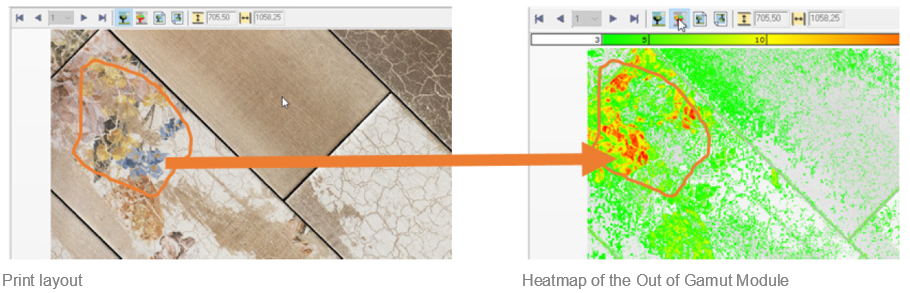

With this, the areas that lie outside the selected gamut and accordingly cannot be reproduced color accurate on the printing system are color-coded in form of a heat map. This provides you with a clear visualization of the color deviations to be expected.

Depending on the strength of the deviation, color-critical areas are shown in green (close to the gamut), yellow (further away from the gamut) or red (far outside the gamut), while all problem-free areas appear in gray. The DeltaE limits for the deviations can be defined individually and thus adapted to the user’s own requirements.

Using the heat map, you can see at a glance which color deviations you can tolerate in the print job, which areas you need to edit, or whether it is better to switch to a production alternative. You can also easily ensure the correct reproduction of spot and brand colors in PDF documents with the Out of Gamut Module.

This allows you to check before production whether the production reference can be reproduced completely on the current production system – directly in the print preview.

This reliable and fast assessment of color-accurate reproducibility reduces the rate of misprints and thus saves resources, time, and money.

If you would like to learn more about the Out of Gamut Module or have any questions, please contact us at contact@colorgate.com. We will be happy to help you!