The challenges in décor reproduction

Décor reproduction is a sophisticated art, focused on bringing designs to life with spot-on accuracy. However, achieving consistent and accurate colors remains a major challenge in this demanding industry, where standards are sky-high. Unpredictable outcomes often occur due to factors such as environmental conditions, as well as variations in ink and substrate. While traditional methods like ICC profiling aim to address these challenges, we recognize the need for another solution in some cases.

In a world where some still cling to hours-long color correction in Photoshop, the burning question is: How to minimize deviations and achieve consistent color reproduction, especially if the goal is to reprint the same designs across several locations?

.png?width=794&height=356&name=MicrosoftTeams-image%20(41).png)

Automated color correction with colorgate

To deal with these challenges, we've developed an automated color correction process that increases the accuracy in color reproduction. But how do we pull it off? The process initiates during the early phases of décor production, precisely when the print data is generated within our Décor Productionserver. At this stage, we create a so-called Fingerprint Production File, which operates like a "digital color twin".

This file becomes the backbone for further production runs, containing all important information from the initial run, including both print data and spectral color references. This "digital color twin" goes through all production steps of the original design, enabling a color-accurate reprint and allowing for a more exact reproduction of a design in every subsequent production. But even here, color deviations can still occur.

That's why we throw the Color Correction Loop Module in to the mix and by measuring a reference status, our module identifies color shifts that exceed predefined limits. It then calculates color corrections, eliminating the need for time-consuming manual adjustments and expert intervention. When integrated with our Fingerprint Module, this system ensures easy color matching in future reprints, automated correction of deviations and completing a highly automated workflow, just like in the graphic below:

.png?width=962&height=452&name=MicrosoftTeams-image%20(42).png)

what do you get from it?

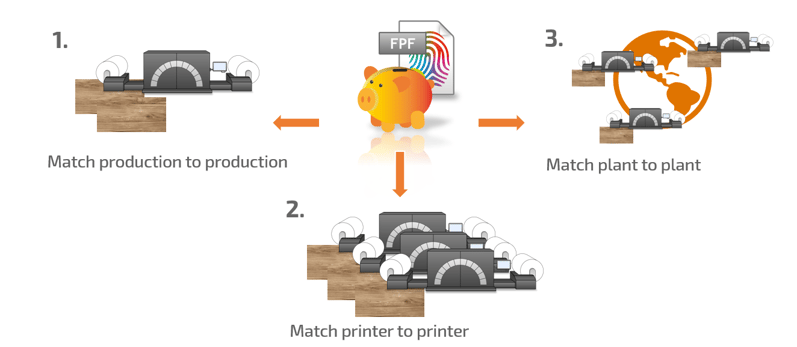

Our automated color correction system not only lightens the workload for your employees but also enables consistent results in a workflow that can be easily mastered by anyone. Meaning you no longer have to rely on individuals to retouch designs by hand on graphic software, which is costly and time-consuming anyway. In addition, you will save valuable time and money while also achieving design consistency across different production locations and devices, in what we call 3xP2P color matching, just like in the graphic below. Experience an enhanced production, aligned with cost savings and reliable outputs!

Embrace a seamless approach to color adjustments with our automated measurement and correction system. Say farewell to manual tweaks as our automated color correction system will help you upgrade your printing workflow.

If you have any questions or wish to discover more about our technology, feel free to contact us any time at contact@colorgate.com

0 Likes